Coating on ceramics is a technological innovation in modern ceramic decoration technology! The metallic feel of the ceramic surface not only increases the wear resistance of the product, but also doubles the price of the product; a creative and modern metallic ceramic work, whether in furniture decoration or decoration A pretty big market!

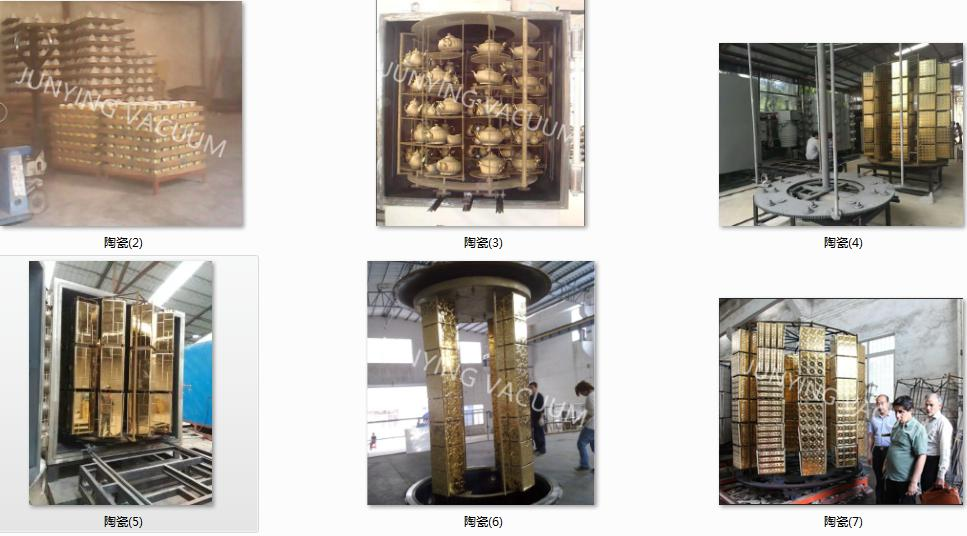

The main equipment used is: Vacuum Ion Coating Machine (PVD)

PVD, or physical vapor deposition, is an advanced surface treatment technology widely used in the world.

The working principle is that under the vacuum condition, the gas or the evaporated substance is separated by the gas discharge, and the vapor or its reactant is deposited on the ceramic while the gas ions or the evaporating substance ions are bombarded. It has the characteristics of fast deposition speed and clean surface, especially the advantages of strong adhesion of film layer, good winding property and wide plating material.

PVD Coating advantage

| Characteristics,advantages | Vacuum coating (with drawing) |

| Strong adhesion, durability, antioxidant | Strong binding to the substrate, in strong sunlight, salty wetlands do not lose luster, do not fade, do not fall off and burst. Highly resistant to oxidation, corrosion and acid. It is resistant to abrasion, scratches and scratches. |

| Clean and easy to clean | Whether it’s the production environment and the surface of the product is very clean, use a soft cloth and glass cleaner to clean the PVD film layer, easy to remove surface paint and fingerprints. (can reduce the time and cost necessary to clean and polish brass or metal) |

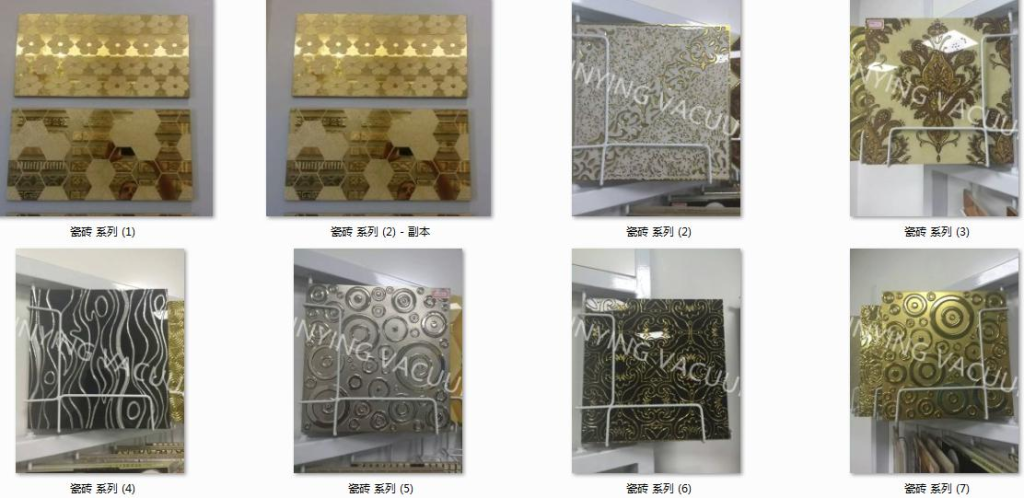

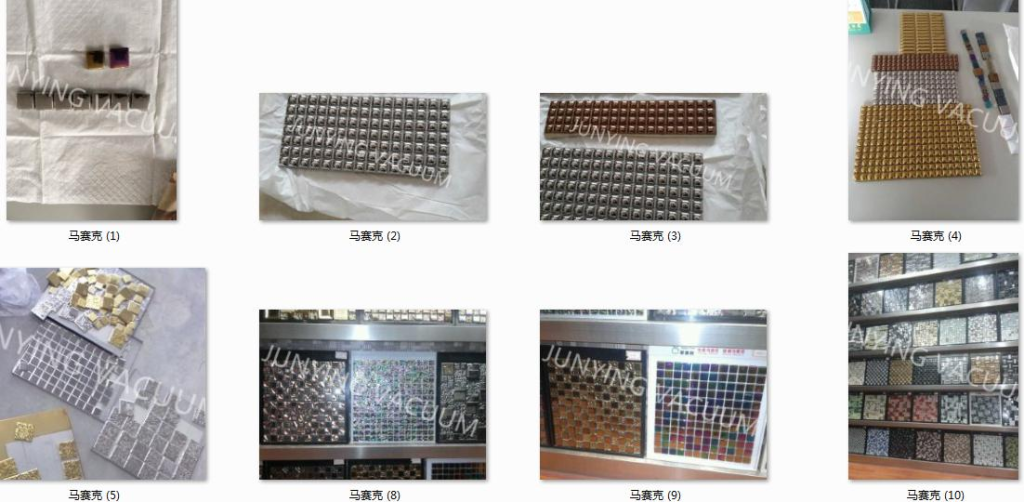

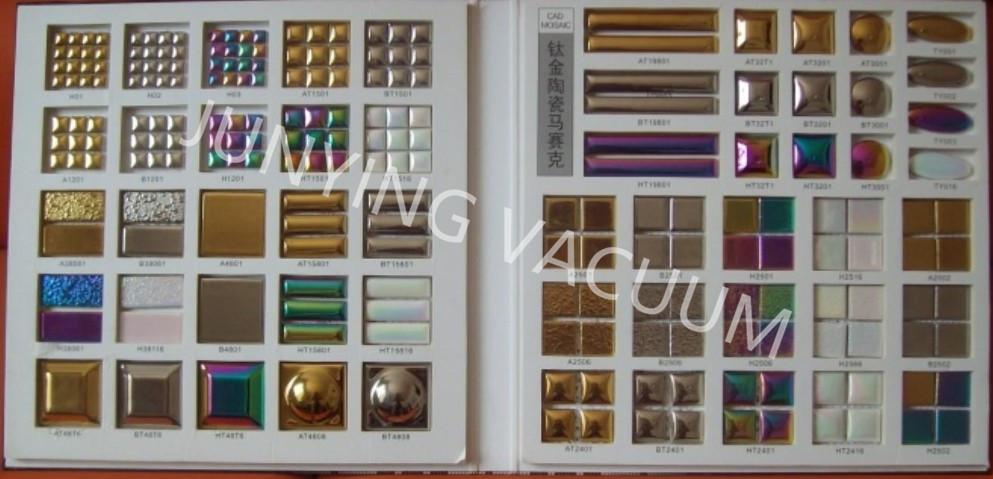

| Various patterns can be etched | Can etch any imaginable design |

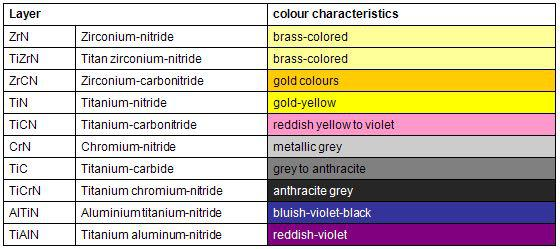

| Rich color plating | Different shades of gold, gray, black, blue, copper, color, etc. |

| Coating uniformity | Uniform, delicate and beautiful |

| Production site | With a small footprint, 1-2 units can be used for large-scale surface treatment. Suitable for manufacturers after processing, or special surface treatment services! |

| Environmental protection | It is harmless to the environment and avoids chemical poisoning and VOC emission. |

| Economy | The main cost of the product is consumables and electricity. The electricity consumption is only 1/10 of that of hydropower equipment, and the consumption rate of consumables is 10 times that of spraying equipment. |

(Before coating)

Production process:

1. Product dry and oil free dust

2.Clamping

3. Into the furnace (because the product is heavier, you need to make the track on the spot, directly into the furnace) (if you need high-end customizable automatic line)

4. Close the coating (30-40 minutes a furnace) (the manufacturer designs the standard for you, one-button operation)

5. Open the door to pick up the pieces

(After coating)

Coating process

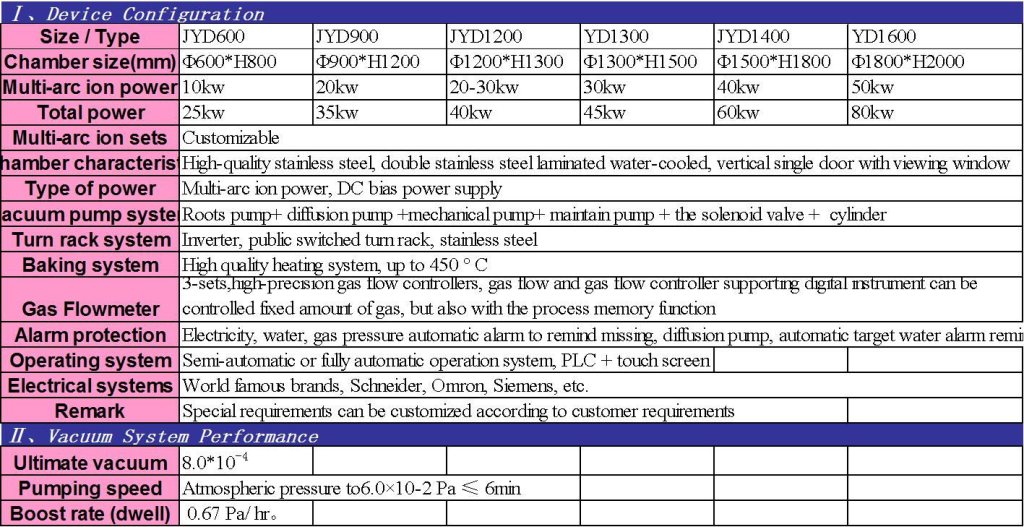

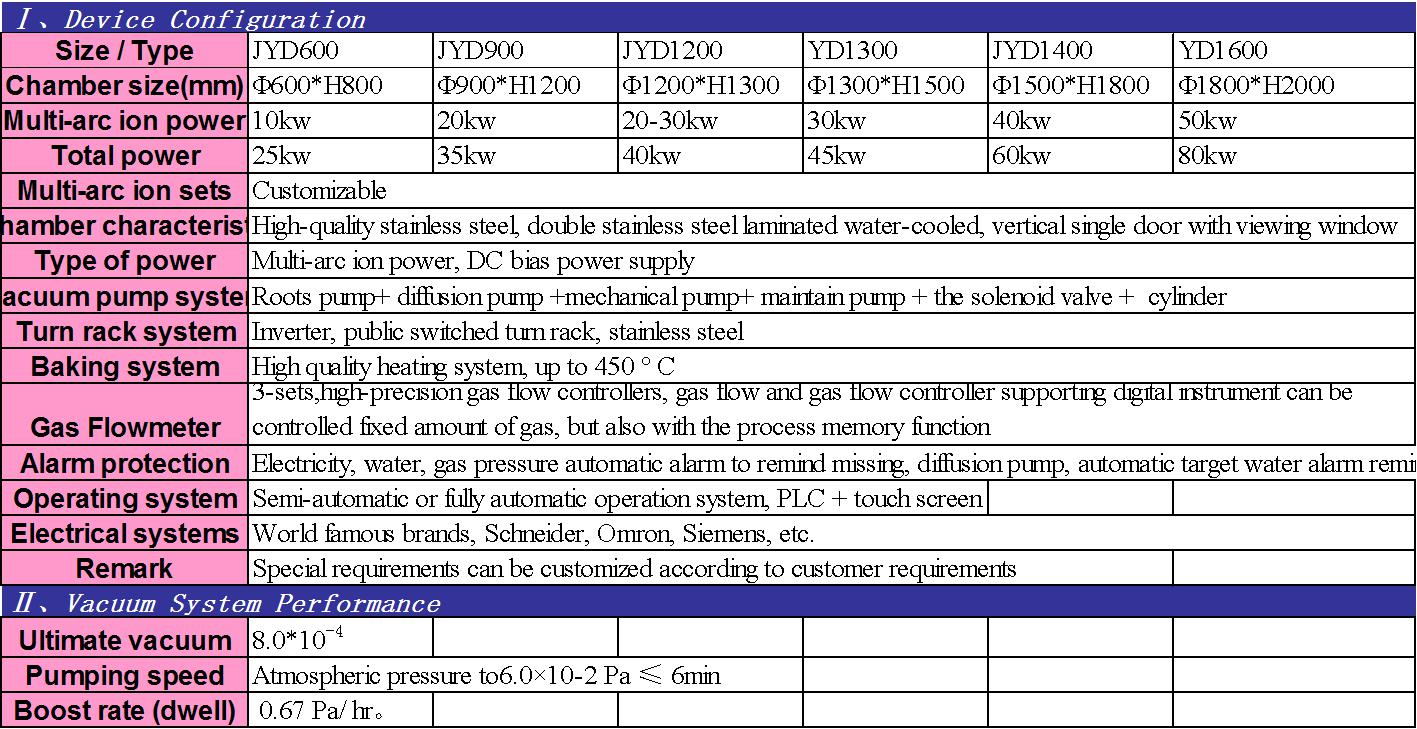

Equipment parameters and configuration

(Give me parameter configuration)

The ceramic factory has all the conditions, only need to add a process

Processing plants need water, gas, electricity, plant area of more than 100 square meters

Our company adopts the world’s advanced magnetron sputtering ion plating and multi-arc ion plating process equipment, and on this basis with the international experts’ process innovation. With more than ten years of valuable experience in the decorative plating industry, we provide our customers with the most suitable coating processing solution.

Junying Vacuum is willing to develop and grow together with my customers. Yuanji wishes you full of energy and good luck!

Leave a reply