PECVD plasma enhanced chemical vapor deposition is a new technology for applying plasma formed by low-pressure gas discharge to chemical vapor deposition. In a PECVD apparatus, a substrate is placed on a cathode of a low-pressure glow discharge, a suitable gas is introduced, and a film is deposited on the surface of the substrate by a combination of chemical reaction and ion bombardment at a certain temperature. Therefore, PECVD includes not only chemical vapor deposition but also plasma plasma strengthening.

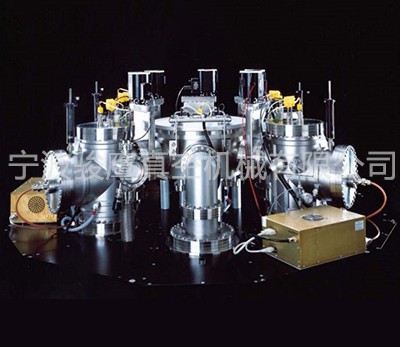

In many plasma generation methods, the Junying PECVD reaction system uses high-density plasma sources such as high frequency (RF-PECVD), microwave (MW-PECVD) and electron cyclotron resonance (ECR-PECVD). Its dense plasma is suitable for thin film solar cells, surface modification, optical and industrial plating, silicon nitride passivation, diamond films and others. The PECVD system available is tailored to the individual manufacturing and R&D needs of the customer.

MW-PECVD

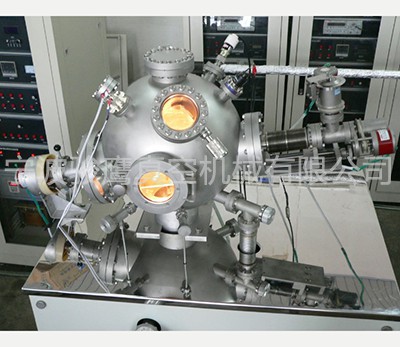

The Junying microwave PECVD system is mainly used to deposit diamond films. It provides a method for producing a variety of films, such as diamond-like carbon (DLC) and single crystal diamond, nanocrystalline diamond, ultra nanocrystalline diamond, and single crystal diamond. Optical performance can range from black to all optical levels. The diamond film can achieve a thickness of 1.2 mm on optical grade diamond and 2 mm on black diamond. Our 915 MHz MW-PECVD system can plate substrates up to 4″ / 100 mm in diameter. For diamonds with diameters of 2″ / 50 mm or less, it is more economical to use a 2.45 GHz MW-PECVD system.

Vacuum chamber: inner cavity size φ500mm (diameter) × 350mm (height).

φ500mm×550mm

φ600 mm×500 mm

φ700mm×500mm

Tel: +86-15888059749

Monday to Friday 9am to 5pm

Reviews

There are no reviews yet.